| HOMEPAGE | BENIN THE HOME OF HEROES | FROM CRADLE TO BOYHOOD AND EARLY PUBLIC LIFE | THE BIRTH OF A DREAM | PRINCIPAL VENTURES |

| E-mail LOGIN |

|

|

THE ESAMA OF BENIN KINGDOM |

|

The Great Life of A Pioneer |

Igbinedion as a Benin family name is now a household word. It has become synonymous with Aviation, Industry, Education, Finance, Medical Care and Rural Development at local, national and international levels. The man who has made this possible in Africa is Sir (Dr.) Chief Gabriel Osawaru Igbinedion, the Esama of Benin Kingdom. Chief Igbinedion has attained great heights in life reminiscent of great achievers. He is a philanthropist and and a humanist of national dimensions and an industrialist of international fame...read on |

PRINCIPAL VENTURES

...'cont'd :: OKADA AIRLINE

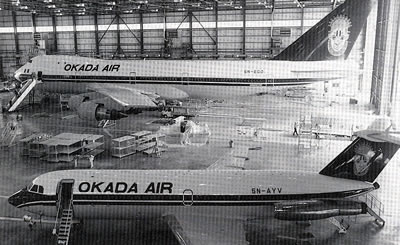

Similar intensive training is being organised on regular basis for the other ranks of the aircraft crew including air hostesses. The training which is undertaken by Aer Lingus, concentrates on cabin manners, safety precautions and courtesy to passengers. Sight is. not lost of the need to improve the quality of its services as a way of cutting down on the response time to passengers' complaints and queries. Moreover, a deliberate strategy of constant monitoring of staff is maintained in order to ensure an untarnished level of staff productivity and efficiency, all in the bid to create a home from home for the Okada Air passenger. Of premium importance to the survival of an airline industry is the maintenance of the air fleet. For this purpose Okada Air maintains an engineering team of indigenous and Philippino engineers. The point has been emphasised that a cardinal aspect of the success story of Okada Airline is its huge investment in manpower training and upkeep. But this is only one part of the deal. The aircraft have to be in a good condition for the flight to be perfectly safe and safety is the ultimate desire of the airline passenger.

Since its inception, Okada Airline has maintained a relatively enviable record in its flight history, with the exception of the slight misfortune at the Sokoto air field where against all odds the pilot successfully avoided a major mishap, the Airline has maintained an impressive safety record over the years, thanks to the ardent attention paid by the Okada Airline to aircraft and crew management. Okada Air has been at the forefront not only in Nigeria but also the whole of Mrica in private aircraft maintenance culture. The Airline's aircraft are regularly checked and serviced by worldwide reputable aircraft manufacturers including British Aerospace, Rolls Royce, Rogers Aviation, FLS Aerospace, Aer Lingus and Israeli Aircraft Industry (IAI). In order to sustain this high level of maintenance culture, Okada Airline maintains aircraft spares stores at Benin City, its national headquarters. Here, all the Airline's serviceable rotables and consumable parts are kept. "The rotable parts are those that are serviced or overhauled locally in our depot. Such parts include, generators, VF. Communications gadgets, hydraulic engine driven pumps, fuel control units, brakes, station boxes as well as vertical speed indicators," disclosed an aircraft engineer in a brief interview. The consumables make up the other type of spare parts which are also kept at the Okada Air Benin depot. The consumables, according to the engineer, are those parts that cannot be serviced, only replaced, such as bolts, nuts, oil seals, washers, and springs. Okada Air's spare parts depot is usually referred to as a bonded store because it houses both rotable and consumable aircraft spares.

The Okada Air depot also houses a quarantine store where unserviceable parts that are to be sent abroad for repairs are kept. The quarantine department is also meant for the storage of new imported spares to be sent to the bonded store only after they had been duly indented and certified by the Nigeria Air Registration Board. The act of keeping an aircraft in the air goes beyond maintaining spare parts stores. Okada Air certainly goes beyond this to keep reCords of the flying hours of every aircraft in the fleet in order to keep track of the maintenance check advice on the aircraft. Perhaps the end point on the maintenance catalogue of the Okada aircraft is the multi-million dollar aircraft hangar built at Benin Airport. Constructed jointly by one of the world's most reputable Aircraft Hangar construction firms; Mero Construction Company of Germany, Soimi (Nigeria) Limited and Pedrocchi Nigeria Limited; the Okada Airline hangar remains conspicuously one of the major edifices of the aircraft maintenance industry. The hangar contains some of the most modern aviation equipments, radio and avionics shops, technical planning and control units and air worthiness directive amongst others. Also available at the hangar are the facilities for carrying out major checks including towing trucks, ground power units and compressors as well as crack testing machines, bendix radar and echo radar scanner. ...READ ON |

:: OKADA AIRLINE :: IGBINEDION EDUCATION CENTRE :: IGBINEDION HOSPITAL AND MEDICAL RESEARCH CENTRE

|

| A great son of Africa who has become a towering international success. This is the powerful moving biography of one man's determination to win- H. R. H. Oba Lamidi Adeyemi lll, The Alaafin of Oyo |

| This remarkable biography weaves the story of an endlessly fascinating man, his family and business empire- Dr. Brian Aghedo PhD |

| Do you have what it takes to be an industrialist, businessman and philanthropist? Chief Gabriel Osawaru Igbinedion's life story tell how, withouth mortaginng your soul- Chief Pearnel Charles, Jamaica |

| Sir Igbinedion is a great man of trmemendous and unqualified resources. His humility and great service to humanity coupled with his willingness to help the less-privileged has earned him respect and admiration the world over- Prince Abubakar Audu, former executive governor of Kogi State, Nigeria. |

| Igbinedion does not believe in failure, he says, "don't be afraid, everyone has them and sometimes they can be resurrected with resounding success- Alfred Eghobamien Esq.SAN |

![]() Afew Acknowledgement of Chief Igbinedion's Sense of Philanthropy

Afew Acknowledgement of Chief Igbinedion's Sense of Philanthropy